Our mobile packing team has done a great job again, this time with an over-sized load in South Wales; Export Packing a Flare Tip heading out to finish off a Flare Stack on an oil rig off the coast of Australia.

DSCN9793

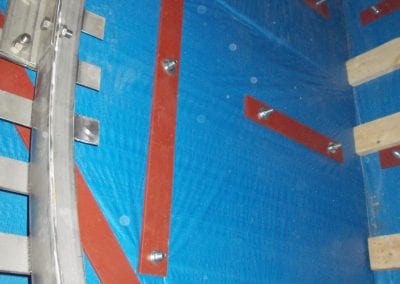

As part of the lifting and moving mechanism, specialist steel has been manufactured to be incorporated into the case

DSCN9816

The steelwork that will go on the outside needs the inside support as well. It is measured exactly to add as much strength as possible

DSCN9769

The steelwork starts to go on the outside, along with the secure lugs that will be used to manoeuvre the case when it comes to loading onto the aeroplane

DSCN9821

The completed outer steelwork. Now that the case and steelwork are completed, the unit is certified for lifting, with all relevant documentation

The steelwork is needed for the lifting to get it into the plane, as it’s too tall stood up, so it needs to be loaded on its side. However, the lifting at its final destination needs to be done with it stood upright. With the steel lugs on its side and two cranes, the case can be easily and safely rotated, while keeping the flare tip completely supported the whole time.

After the case is finished, it’s then a matter of getting it where it needs to go. With a case this large (456 x 387 x 384 cms), and when time is of the essence, the only option is the famous Antonov: